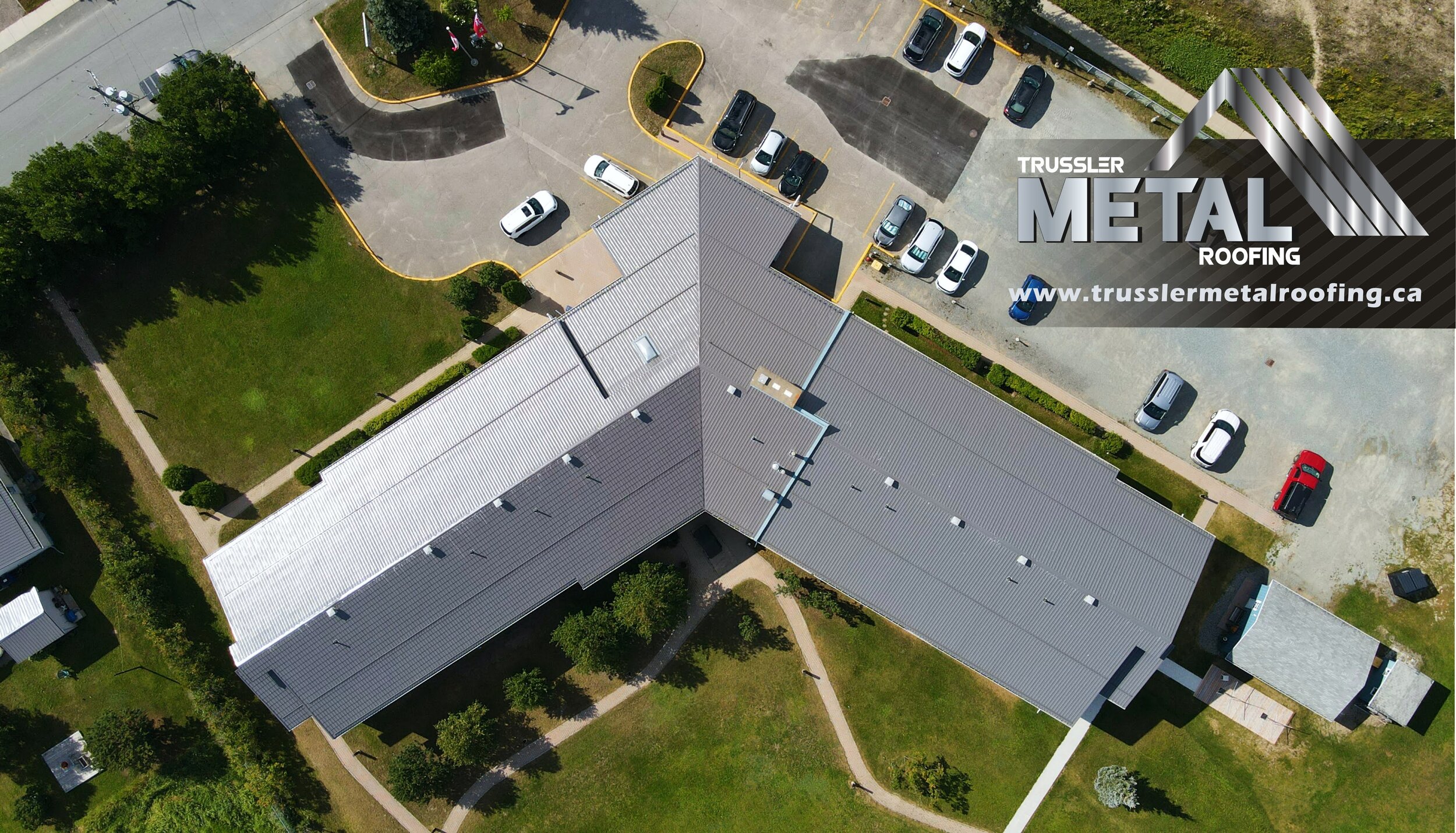

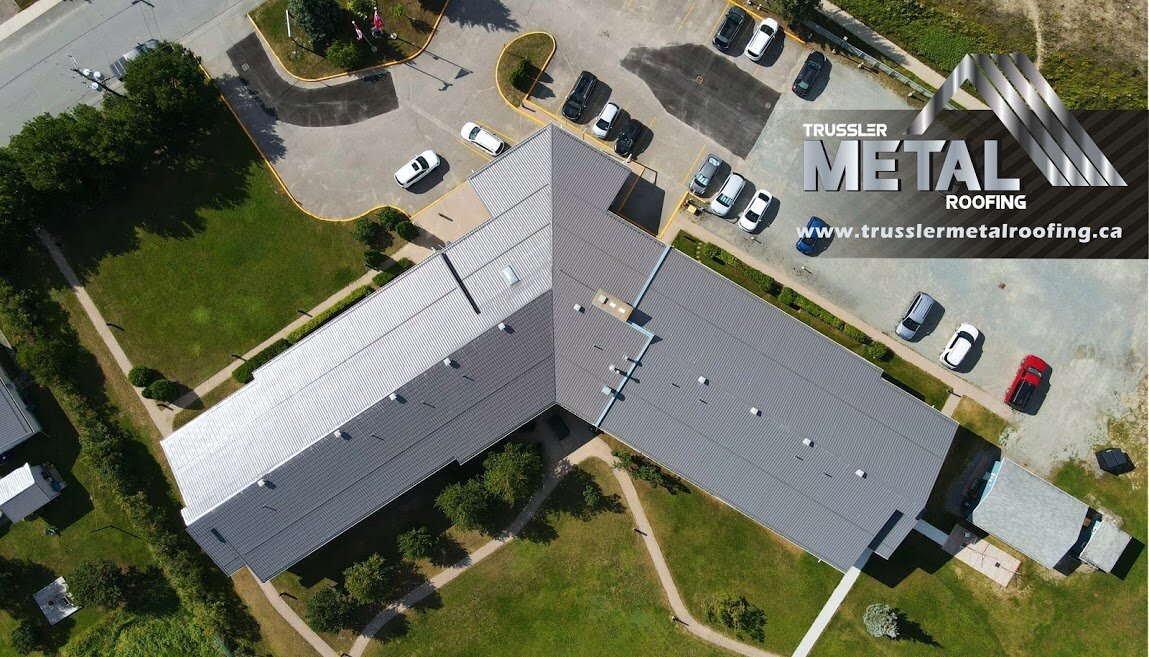

ECO LODGE

PROJECT DESCRIPTION

Commercial building

61 Hospital Dr.

Moose Factory

Material: Snap Lock

Color Choice: Copper

Sq. Footage: 5000

_____________________

This 2000 Square foot building has Copper Snap Lok 26 Gauge panels from Westman Steel. This job had two major problems. The first major problem was inadequate insulation and vapor barrier and the second major problem was low-grade peel-and-stick asphalt roll roofing. Upon removing the roll roofing water seepage and fiberglass batt insulation were found. The batt insulation was in very poor condition due to an annual cycle of being wet then dried from frost, building up then melting over and over again. In the cold season, heat from the interior building would penetrate inadequate insulation and poorly applied vapor barrier and form frost on the bottom of the roof deck. As the warm season approached the frost would melt, saturating the insulation and then leaking into the building. As the hot summer season presented itself the moisture would dry out. The insulation loses its R-Value from this reoccurring problem getting worse every year.

We removed the roll roofing and the plywood roof decking exposing the insulation batts. We removed all the insulation and applied the 2 lbs close cell spray foam insulation in its place. Close cell foam does not allow moisture to penetrate it, it is a complete vapor barrier. We applied it to a thickness to achieve an R 60 Value. We built a new roof deck with ventilating channels below the metal panels. Metal panels were installed. Style Snap Lok (hidden fastener).

FYI: by tackling the inadequate insulation problem from the exterior nothing was disturbed on the interior. The business was not interrupted and was able to stay open. This same concept can be applied to residential homes so that no disturbance is caused. This is a low-impact solution to tackling two problems that often go hand in hand. HEAT LOSS and LEAKY ROOF = BIG PROBLEMS.

About Spray Foam. By doing Spray Foam they have strengthened their roof system. When the spray foam binds to the structural rafters it creates a bonding between each rafter. The Spray foam adds more tensile strength to the complete roof structure. (Tensile Strength: the resistance of a material to breaking under tension.)

Project duration: 10 days The Eco Lodge is now saving on heating and cooling costs and no longer has seasonal leaking.